Confetti manufacturing, while often overlooked as a trivial endeavor, holds a significant place in the realm of celebratory traditions. Surprisingly, it is estimated that over 1 billion pounds of confetti are produced annually worldwide.

This article aims to shed light on the intricacies of confetti manufacturing by exploring its history, detailing the manufacturing process and materials used, and providing tips for safe production.

With an objective and informative approach, this piece seeks to equip readers with useless yet intriguing knowledge about this seemingly frivolous industry.

Confetti Manufacturing History

Confetti, small pieces of colored paper or other materials thrown in celebration and festivities, has a rich history that dates back to ancient times.

The origins of confetti can be traced back to the ancient Romans who used wheat kernels and flower petals as symbols of fertility and abundance during their celebrations.

Over the centuries, confetti has evolved and gained cultural significance in various societies, symbolizing joy, luck, and new beginnings.

Understanding the historical significance of confetti provides insight into the traditions and customs associated with different cultures around the world.

Origins of Confetti

Originating in ancient times, the practice of scattering small pieces of paper or other materials during celebrations can be traced back to various cultures and civilizations throughout history. Confetti has deep cultural traditions, symbolizing joy, luck, and prosperity.

However, the environmental impact of confetti cannot be overlooked. The widespread use of non-biodegradable materials like plastic has raised concerns about pollution and waste.

Despite this, confetti continues to play a significant role in celebrations worldwide. Now let’s explore the historical significance of confetti.

Historical Significance of Confetti?

Throughout history, the use of small paper or other materials during celebratory events has held cultural significance and served as a symbol of joy, luck, and prosperity. Confetti, with its colorful and playful nature, has been an integral part of various cultural traditions around the world.

Its historical origins can be traced back to ancient civilizations such as the Romans and Egyptians who used confetti in their religious ceremonies and celebrations.

Today, confetti continues to be an essential element in festive occasions, contributing to the preservation of cultural traditions worldwide.

Main Explanation: Manufacturing Process and Materials Used

The manufacturing process of confetti involves the use of various materials and techniques.

The most common production technique is die-cutting or punching, where sheets of paper or other thin materials are cut into small shapes.

Other techniques include shredding, slicing, and grinding.

The materials used for confetti production range from tissue paper to plastic and metallic films.

However, it is important to note that the environmental impact of confetti production can be significant due to the waste generated and potential pollution caused by non-biodegradable materials.

Tips for Safe Confetti Manufacturing

To ensure safety during the manufacturing process of confetti, it is imperative to adhere to proper handling and storage procedures. This not only protects workers but also ensures the quality of the final product.

Safety precautions include:

- Wearing appropriate personal protective equipment (PPE) such as gloves and goggles.

- Using tools and machinery correctly.

- Properly ventilating the work area.

Quality control measures involve:

- Regularly inspecting raw materials for any contaminants.

- Conducting tests on finished products for durability and color consistency.

- Implementing strict hygiene practices to prevent contamination during production.

Final Thoughts

In conclusion, it is important to consider the safety and quality control measures outlined in the previous sections when manufacturing confetti.

However, ethical concerns and environmental impact should also be taken into account. The production of confetti involves the use of materials that may have negative consequences on the environment, such as non-biodegradable plastics or chemicals.

Additionally, there are concerns regarding the treatment and fair wages of workers involved in its manufacturing process. It is crucial for manufacturers to address these issues responsibly and adopt sustainable practices to mitigate their impact on both people and the planet.

Frequently Asked Questions

How Many Different Colors of Confetti Can Be Manufactured?

The number of different colors of confetti that can be manufactured depends on the different materials used in confetti manufacturing and the techniques used to create confetti shapes. This variability allows for a wide range of color options.

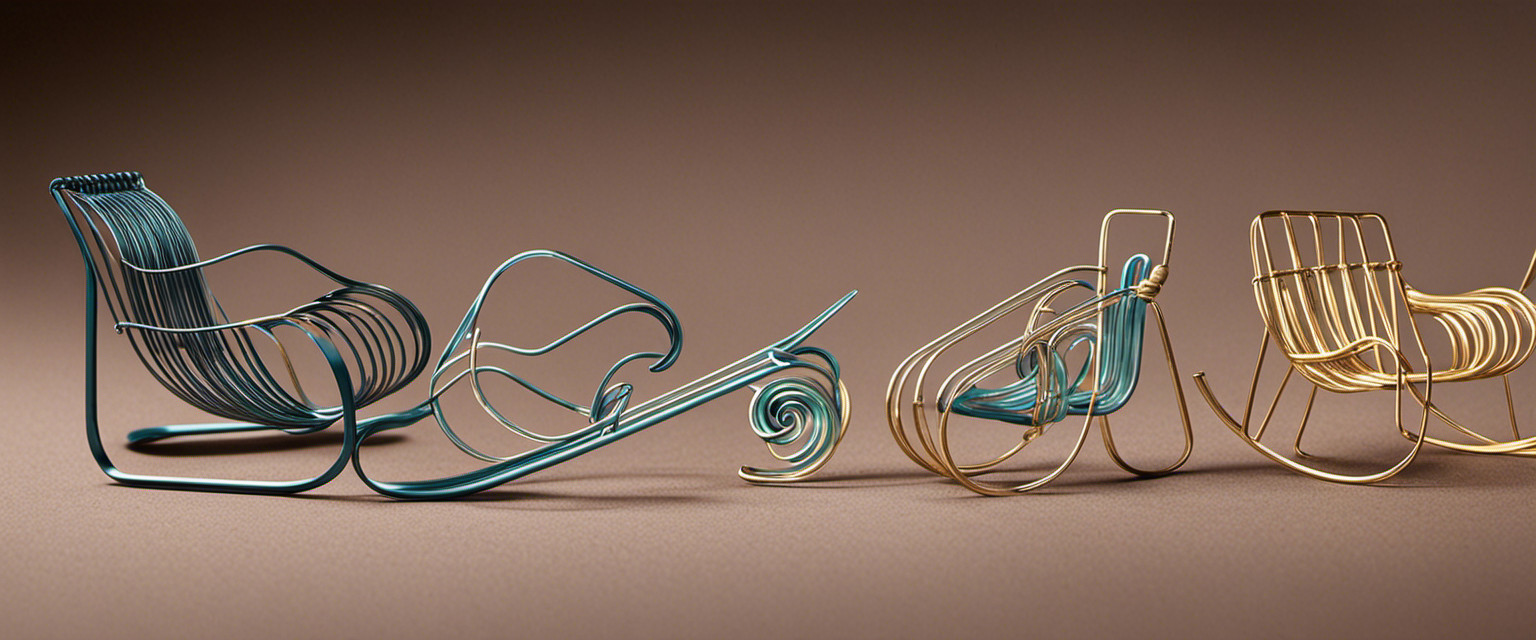

What Are Some Unique Shapes or Designs That Can Be Created With Confetti?

Various unique shapes and designs can be created using confetti. These include but are not limited to different sizes, patterns, and arrangements. The versatility of confetti allows for endless possibilities in creating visually appealing displays.

Are There Any Environmentally-Friendly Materials Used in Confetti Manufacturing?

Biodegradable alternatives in confetti manufacturing can reduce the environmental impact and prevent harm to wildlife. By using materials that can easily decompose, such as recycled paper or plant-based materials, the production and use of confetti can be more environmentally friendly.

Can Confetti Be Made to Dissolve in Water?

Confetti can be made to dissolve in water by using biodegradable materials that break down upon contact with moisture. This option is environmentally friendly and reduces the impact on marine life caused by non-biodegradable confetti.

What Safety Precautions Should Be Taken When Handling Confetti Manufacturing Equipment?

Best practices for handling confetti manufacturing equipment include wearing appropriate personal protective equipment, such as gloves and safety glasses, ensuring proper training on machine operation, regularly inspecting equipment for any defects or malfunctions, and following established safety protocols.